Simple Seating

Over the past several months I have been designing a new line of seating, and just last week I added the final designs to my portfolio. I wanted to blend traditional chair design with a modern touch and am very happy with the outcome. This collection of bar stools and dining chairs are a no nonsense approach to seating.

The 'Gudde Dining Chair,' 'Modern Dining Chair,' and 'Modern Barstool' have a welded steel frame with an inset hardwood backrest, and fitted hardwood seat. The back legs splay out to give a subtle yet appealing design touch that matches the angle of the backrest. The seat tapers from the front to back of the chair, being fitted in between the backrest frames for a clean and fitted seat.

For those wanting a more traditional design with an industrial look, I made the the 'No Nonsense Bar Stool.' Living up to it's name, this stool is simple ⏤ a square steel base with two footrest placements and a hardwood top.

All simple seating designs are available for order in a variety of hardwoods and steel base finishes, at chair (18"), counter (25"), or standard barstool (30") heights.

Contact me if you're interested in placing an order!

Upcoming Gallery Feature!

I have been given the opportunity to be part of an upcoming gallery exhibition in Austin. The exhibition will run from April to July, near downtown Austin, and feature several Gudde Co pieces. This will be a great opportunity to not only showcase my work but also tell the story of some of the local pieces I've created.

On top of that exciting news, the gallery exhibition occurs during the West Austin Studio Tour weekends (May 13-14 & 20-21). The West Tour (for those not in Austin) is a free, annual, self-guided art event giving the public an opportunity to meet local artists and artisans of Austin. It's quite a big deal in the arts community! During these West Studio weekends, I will showcase additional Gudde Co pieces at the gallery and be on-site to talk about my work and the displayed pieces.

I am honored that the gallery selected me and my work as the feature of the upcoming exhibition. I can't wait to see the response during both the exhibition and West Tour weekends!

*More details will follow, as the exhibition date gets closer!

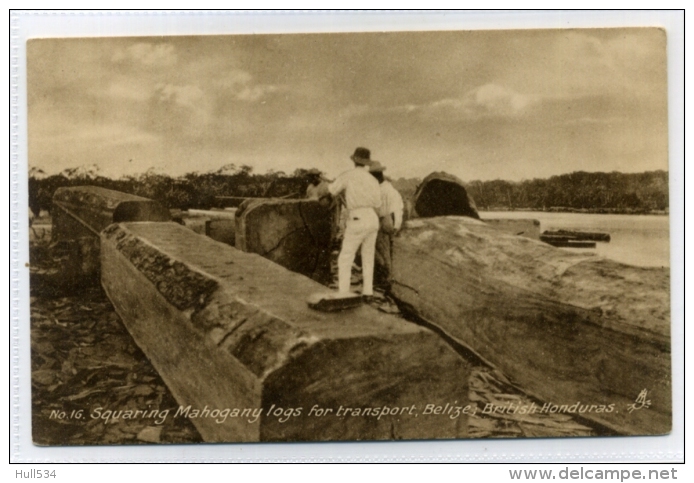

Recently Delivered Pieces

2017 started off with a bang! I completed 9 pieces in January, shipping them off to great clients across the US!

Keep up with our latest projects. Follow us on social media!

Recommend us to family and friends!